Blog

A Major Upgrade to PO Management: Introducing Split Deliveries

A Major Upgrade to PO Management: Introducing Split Deliveries

Laura B

Marketing Analyst

Nov 30, 2025

The Problem with Single-Delivery POs

In the complex world of retail and D2C, one of the most fundamental challenges lies not in what you order, but in how you receive it. For any scaling business, there is a core tension between the strategic decisions made in procurement and the operational reality on a warehouse floor. This tension is never more apparent than in purchase order management.

The traditional purchase order has always been a flat document, a single line item with one massive quantity and one expected delivery date. This creates a significant disconnect between the plan in the system and the reality on the ground. This single-delivery logic makes accurate inventory forecasting impossible. Your replenishment planning might see twelve thousand units "arriving" in March, when in reality, you had only planned to receive one thousand.

This lack of true supply chain visibility forces you to plan using inaccurate numbers instead of your real, agreed-upon delivery schedule. It can also turn tracking partial shipments into a operational headache, forcing your team to use manual spreadsheets and making it one of the weakest links in your entire supply chain.

What is a Split Purchase Order?

This is where a split purchase order—also known as a phased purchase order, planned purchase order or a PO for multiple deliveries—becomes a strategic necessity.

At first glance, it may seem logical to just place twelve smaller, monthly purchase orders, one for each delivery. But smart procurement almost always relies on a single, massive purchase order placed for an entire season or year. There are powerful financial and logistical reasons for this.

→ The Smart Move: As a business scales, it's smart to place one massive annual PO for 1,200 t-shirts. Why? This way you secure bulk pricing, protecting you from price hikes. A supplier will always offer a much better per-unit price for a guaranteed order of twelve thousand t-shirts than for a small, one-time order of one thousand. Just as importantly, that large order guarantees production capacity. When a supplier receives a single, annual contract, they reserve that stock and that space on their manufacturing line for you. You are no longer a small customer hoping to get an order filled during a busy season; you are a key partner with guaranteed inventory. By committing to the full volume upfront, a retailer locks in that favorable price for the entire year, protecting itself from future cost increases.

A split purchase order is the elegant solution that honors both goals. It is a single, binding contract that locks in the bulk price and total quantity, while also containing a detailed schedule of the smaller, phased deliveries. It is the key to managing supplier delivery schedules without sacrificing your strategic advantage.

How to Improve Split Inventory Intake

The challenge, therefore, isn't just conceptual. It's technological. The primary reason businesses still struggle with partial purchase order shipments is that their software isn't built to handle them. You may have a real-world plan for a split intake, but if your system can't track it, you can't forecast from it.

The solution is to adopt PO management software that was designed for this reality. You need a tool that can understand and track a single PO with multiple, scheduled delivery dates. This is the only way to bridge the gap between your procurement strategy and your operational reality, and it's precisely why we built our new feature.

Introducing Tightly’s “Splits” PO Feature

We are thrilled to announce the launch of Tightly's new Split Purchase Order Deliveries feature, designed to bridge this exact gap between your digital PO and your physical deliveries.Previously, Tightly’s purchase orders were binary: you placed an order, and the system expected a single delivery date. Because the system couldn't track a complex schedule, it was difficult to reflect your real-world delivery dates. This made tracking partial receipts messy and it created a disconnect in your cash flow planning.

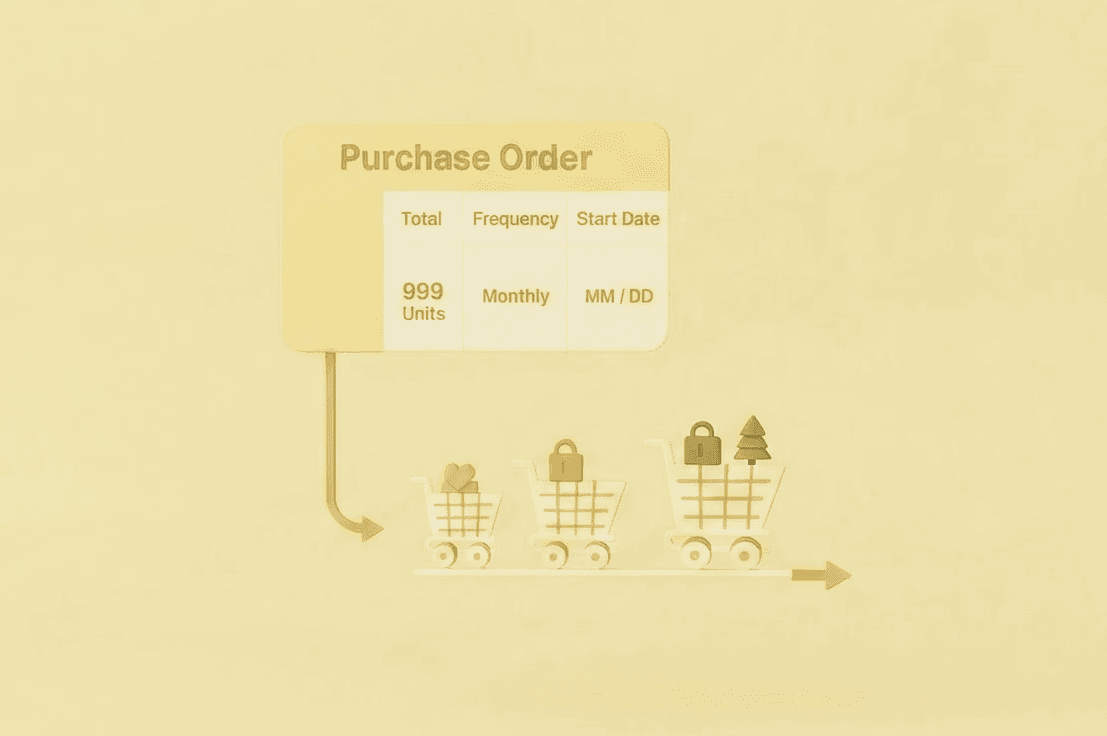

But this new feature now allows you to take a single, large Purchase Order and break it down into multiple, scheduled shipments. Instead of receiving everything at once, you plan to receive the inventory in waves over a period of time. It enables you to define a clear and specific delivery schedule. You can choose from standard frequencies for a recurring purchase order (like Monthly or Quarterly drops) or build a completely Custom schedule with unique dates and quantities.

Once you set your frequency and start date, Tightly automatically distributes the total PO quantity across the planned delivery dates. For example, a 12,000-unit order set for a Monthly schedule will be automatically split into twelve 1,000-unit planned deliveries.

Crucially, once this purchase order is confirmed with your supplier, this schedule of planned deliveries becomes locked. This ensures both you and your supplier are aligned with a single, consistent source of truth, improving supplier coordination and accountability.

Of course, we also understand that unexpected shipments happen, but our new system still gives you the flexibility to account for any ad-hoc shipments without altering your original agreement. For example, when the April box arrives, your team can now receive that delivery against "Delivery 4" in the system. And if an unexpected shipment arrives, you can still add it as an "Instant Delivery" without altering your original agreement. It is a complete solution to manage multiple deliveries for one PO in a single place.

→ How to Set Up Split Deliveries

You configure this while the Purchase Order is still in Draft Status. The workflow requires you to define three key elements once you hit the “Plan Future Delivery” button under Deliveries, on the Supply Orders tab:

Number of Deliveries: How many distinct shipments will this order be broken into?

First Expected Delivery Date: When will the first shipment arrive?

Delivery Frequency: How often will subsequent shipments arrive?

→ How Inventory is Distributed

For this version of the feature, the system handles the math for you automatically and attempts to distribute the products evenly across the number of deliveries you selected.

Constraint: You cannot manually change the product amounts for specific deliveries in this version. The system defaults to the "most common case," which is an even split across the timeline.

→ Confirmation and Execution

Once the PO is confirmed, these planned deliveries become locked. This is a safety feature designed to ensure consistency between your internal system and the agreement you made with your supplier.

However, the system remains flexible during execution. You can record actual deliveries against the schedule as they arrive. If you receive an ad-hoc shipment that wasn't part of the original schedule, you can add Instant Deliveries without altering the original locked plan.

The True Impact: Aligning Replenishment Planning with Realistic Delivery Dates

The most powerful part of this update is how it transforms your inventory replenishment planning. These new, detailed delivery schedules feed directly into Tightly’s replenishment forecasts, making it one of the most practical supply chain planning tools in your arsenal. This connection is absolutely critical because supply chain visibility isn't just about tracking boxes; it starts with having clean, precise data in your own system. The ability to natively handle a split purchase order and manage multiple deliveries for one PO is what elevates a tool from a simple order-placer to a true solution.

Your planning is no longer based on that single 10,000-unit drop. Instead, accurate forecasting is guaranteed as it is now based on the actual, agreed-upon schedule of smaller, split deliveries. This provides a far more realistic and accurate visibility of your future inventory, allowing you to finally plan your cash flow, marketing efforts, and operations around a replenishment schedule that you know is correct.

This capability allows your business to operate more intelligently. You get to keep the powerful, strategic advantages of placing a large annual order, while finally giving your operations and planning teams the accurate, real-time data they need to manage the day-to-day.

Who is this for?

This new feature is a game-changer for mid-market and enterprise retailers who coordinate recurring shipments with their suppliers. It's built for procurement and supply chain teams who are tired of managing complex, split inventory intake on separate spreadsheets. If you are using Tightly for advanced replenishment planning and purchase order management, this update will bring a new level of control to your entire supply chain.

Laura B

Marketing Analyst

Share